Shop Services

AC & DC Motor Repairs

Our electric motor repair service identifies and remedies the wear and tear which is typically seen in all electric motors over time.

We can refurbish your electric motors and have them back in operation for years to come.

Contact us to discuss your specific electric motor application.

EASA Member

Arm-Tech Electric Motors and Repairs is part of the Electrical Apparatus Service Association which serves to educate and

guide industry with the latest materials, equipment and state-of-the-art technologies.

http://easaontario.ca/

Vibration Analysis

Vibration testing can identify and correct problems by identifying imbalances, premature wear and other issues which allows

corrective measures to be taken before component failure occurs. This procedure is generally regarded as preventative maintenance and

should be part of a regular testing routine.

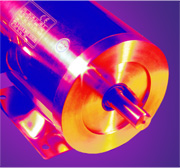

Infrared Scanning

Oil Analysis

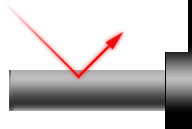

Laser Alignment

Performs critical alignment analysis on rotating machinery to insure accurate tolerances as well as maintain operating performance.

Laser alignment is much more accurate than tradiational dial indicators.

Computer reporting indicates the variances and corrections to be made both during and after corrections have been made.

Laser alignment is much more accurate than tradiational dial indicators.

Computer reporting indicates the variances and corrections to be made both during and after corrections have been made.

Balancing